APEX Biodigester Sewage Treatment Plant

The APEX Biodigester sewage treatment plant superceeds our very successful Falcon and Pureflo Range.

Designed for use where the installation of a septic tank is either unacceptable or impractical and a connection to the main sewer impossible. These plants are particularly useful for situations where intermittent flow, very low flow and seasonal fluctuating flow rates cause serious problems for other sewage treatment systems. They are ideal for campsites, caravan parks, holiday parks, etc. as the APEX Biodigester has a unique recycling system which balances the flow in these situations.

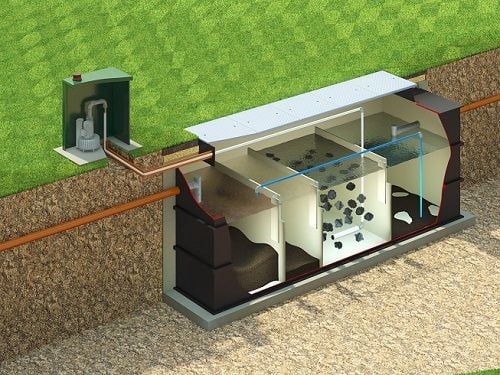

The plant illustrated is a APEX 70 person system.

| Electricity required | YES (Very Low) |

| Emptying Interval | 6 to 12 months, depending on use |

| Primary tank | YES |

| Internal moving parts | NO |

| Concrete backfill | YES |

| Performs during intermittent use (holiday lets, etc.) | YES |

| Visually intrusive (large lids, kiosk, etc.) | NO |

| Expensive servicing | NO |

| Tank Warranty period | 10 Years |

| Easy Installation | YES |

The APEX biodigester sewage treatment plant offers an extremely efficient and unobtrusive means of sewage disposal.

Manufactured entirely from robust and corrosion free materials, the APEX biodigesters incorporate unique and patented features to ensure simplicity and efficiency of operation whilst being able to consistently achieve the ever more stringent standards of discharge effluent quality being required by the Environment Agency. Available in a range of sizes to suit virtually any application from a single residential property, caravan parks, hotels and restaurants or a major industrial / commercial complex, the APEX meets the specific requirements of each individual situation.

The APEX Biodigester has the EN 12566-3 2005.

Features of the APEX Biodigester 6 to 300 person sewage plant range

- EN 12566-3 certified

- Very low electric consumption

- Very clean effluent giving 11mg/litre BOD and 7mg/L Ammoniacal Nitrogen as an average during the EN12566-3 performance test.

- One piece tank construction - the APEX can never leak, unlike many plants made in 2 pieces

- May discharge to a ditch or watercourse, under the Environment Agency 'General Binding Rules' without a Permit.

- Very Quiet operation

- Can be left for up to 4 months without the need for re-starting due to the bacteria being trickle fed with food during absences.

- Gravity and pumped outlet options

- Alarms are standard

- 10 year tank warranty

- Can be designed to be installed above ground if required

- Can be made to suit any drain depth

- Sludge Return facility enables holiday absences and denitrification

- Mobile, containerised sewage treatment system option for oil fields, refugee camps, disaster zones, etc.

What makes the APEX Different?

The APEX is special.

It has a feature that set it apart from normal Domestic Sewage Treatment Plants:

- Automatic Settled Sludge Return (SSR)

Automatic Sludge Return

This used to be a feature of most small treatment systems, but was removed in a Cost Saving excersise by most manufacturers because:

- No-one knew what it was for

- No-one therefore asked any questions about it when it was removed by the manufacturers

- It saved the manufacturers hundreds of pounds per plant, so almost all the competitors followed suit and joined the price war.

What Does The SSR Do?

The SSR recycles live sewage digesting bacteria from the final settlement tank to the first settlement tank to mix with the raw incoming sewage and start the digestion process. As the APEX is a gravity system, the same volume of sewage effluent that has been returned then flows to the biozone digestion chamber, loaded with food from the first settlement tank, which acts as a 'larder' and feeds the bacteria in the biozone even when you are on holiday. This is a continual process and the bacteria can be kept alive for 4 months by this feature. It also allows the plant to work efficiently even when severely underloaded. The APEX kept this process as, although it added to the cost of production, it is such a valuable feature for reliable sewage treatment and houses which are occupied by only one or two people.

The APEX system has been tested for 38 weeks in Germany for BS EN 12566-Pt3 and has produced some of the best results in the market place, 20BOD-30SS-20NH4 being the standard to achieve.

The APEX system has been tested for 38 weeks in Germany for BS EN 12566-Pt3 and has produced some of the best results in the market place, 20BOD-30SS-20NH4 being the standard to achieve.

The APEX sewage plant actually achieved a 96.2% treatment efficiency ratio in the EN 12566-3 2005 test, which equates to 11BOD-16SS-7NH4, a far better quality of effluent than the vast majority of the competition.

APEX sewage treatment plants are offered with a 10 year warranty on the tanks and a 2 year blower warranty. Our price also includes for a compressor failure alarm system as standard, which also forms part of the mandatory requirements.

Installation of the APEX biodigester requires no specialist equipment and can be carried out by any competent contractor, quickly and simply. Once installed, the APEX is completely unobtrusive, even the largest plants.

Details of the APEX Biodigester Package Sewage Treatment Plants

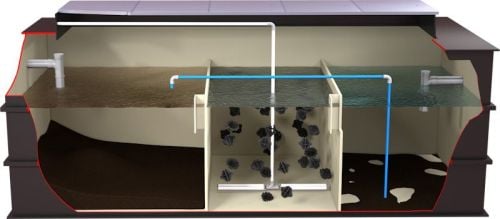

The diagrams show a larger plant for ease of reference, but the smaller circular plants (up to 18 persons) use an identical process.

The APEX wastewater treatment plant is of a single tank design and incorporates Primary Settlement (PST) Biological Treatment (Biozone), and Final Settlement (FST) within the same structure, allowing delivery to site as a complete unit to provide for a simple and straightforward installation. No other tanks are required except for larger applications ( over 300 p.e. ) where a modular system is provided or where additional treatment may be required to achieve more stringent effluent quality standards or where effluent re-use is proposed. The APEX sewage treatment plant has been designed to optimize the aesthetic qualities of the final installation by ensuring that there is minimum visual impact. The APEX process is also designed in accordance with the requirements of BS 6297.

Biological Treatment (Biozone), and Final Settlement (FST) within the same structure, allowing delivery to site as a complete unit to provide for a simple and straightforward installation. No other tanks are required except for larger applications ( over 300 p.e. ) where a modular system is provided or where additional treatment may be required to achieve more stringent effluent quality standards or where effluent re-use is proposed. The APEX sewage treatment plant has been designed to optimize the aesthetic qualities of the final installation by ensuring that there is minimum visual impact. The APEX process is also designed in accordance with the requirements of BS 6297.

Primary Settlement Tank

Raw sewage enters the primary settlement tank. The Primary settlement tank is a two stage tank designed to maximize the removal of gross and suspended solids prior to transfer of the settled effluent to the 2 stage biozone for treatment. The primary settlement tank also incorporates for a sludge storage volume (based on full load) depending on the desludge periods as identified for individual applications.

Biodigester Biozone

The biological treatment phase of the sewage treatment plant utilizes BAF technology (biological aerated filter) which incorporates two proven principles of biological process in the form of a fixed film reactor for process stability and a suspended floc dispersed growth system for high transfer rates and operational control, to ensure a stable treatment process which is largely unaffected by shock loads. Air is blown in from the blower unit, housed in a Kiosk which is supplied with the APEX plant. The sewage treatment process incorporates a submerged plastic media on which a fixed film of friendly, sewage digesting bacteria grows. This film feeds on the sewage liquor passed from the settlement tank and is provided with oxygen by means of a small blower unit which aerates the media through HDPE membrane diffusers to provide fine bubble aeration. The action of the fine bubble aeration is carefully controlled to provide optimum oxygen transfer rates.It also gives a scouring action to slough off excess biomass to keep the thickness of the fixed biological film at optimum levels, ensuring maximum sewage treatment process efficiency. The fact that the media remains submerged allows for an element of suspended floc dispersed growth, which basically means that there will be bacteria which is unfixed to the media but achieving sewage treatment as a biological 'soup'.

The biozone incorporates a two stage process as standard that allows for constant mixing of incoming settled effluent to provide optimum treatment stability and to avoid any short-circuiting. The use of a two stage biozone in the sewage treatment plant ensures a high degree of process efficiency to not only reduce B.O.D. levels to that required, but will also achieve reductions in ammoniacal nitrogen way in excess of standard requirements

The biozone incorporates a two stage process as standard that allows for constant mixing of incoming settled effluent to provide optimum treatment stability and to avoid any short-circuiting. The use of a two stage biozone in the sewage treatment plant ensures a high degree of process efficiency to not only reduce B.O.D. levels to that required, but will also achieve reductions in ammoniacal nitrogen way in excess of standard requirementsFinal Settlement Tank

The final settlement tank is designed in accordance with the requirements of BS 6297 to ensure relevant surface areas and rise rates are achieved to provide maximum settlement of any suspended solids prior to discharge. The APEX sewage system also incorporates continuous and automatically timed humus sludge return systems to return humus sludge from the final settlement tank, back to the primary settlement tank. This is the special function that 'feeds' the bacteria whilst you are away on holiday, a feature that is missing on most modern sewage treatment plants, but remains on the APEX. Additionally this sewage system also provides for continuous recycling of treated effluent back to the P.S.T. to not only provide dilution of incoming wastewater, but to also ensure continuous flow during periods of low or no flow, thereby keeping the biomass in prime condition. It also enables denitrification, further reducing the ammonia in the final effluent.

The APEX below was built to fit into a container for shipment to Iraq.

The final photo is a APEX 100 person built into a container as the tank itself

Please read Tank Delivery and Off-Loading Information before ordering.

APEX 25 person plant installed

APEX 70 person sewage treatment plant installed.

Servicing APEX sewage plants is arranged through Sapphire Environmental Ltd.

DOWNLOADS

APEX 6, 9, 12, 18, 25