QUANTUM Low Cost Small Sewage Treatment Plant

QUANTUM is the least cost and smallest sewage treatment plant in the UK. Retail prices from £1,800 inc. VAT, delivered.

- Low purchase price

- Low installation cost

- Ultra compact, small tank – smallest on UK market

- No blower kiosk (gravity outlet model)

- No odour

- Low noise

- Made in UK

- Can be used as a low cost septic tank conversion unit

Our QUANTUM sewage treatment plant is a low cost, advanced Activated Sludge Process (ASP).

It is designed to receive wastewater (sewage) and process it so that only a clear effluent is discharged into the environment after treatment.

QUANTUM is an economy version of our flagship VORTEX sewage treatment plant.

It is an ideal “all rounder” for domestic properties offering good performance in a very low cost tank.

Features of the QUANTUM Sewage Treatment Plant

-

Extremely clean effluent - up to 97.3% pollutant reduction.

-

Made in UK.

- Exremely quiet operation.

- Odourless - complete aerobic digestion throughout the sewage treatment plant.

- Minimal visual impact - Small in size, only the small tank lid is visible. The low energy blower is housed in a watertight housing under the lid, so there is no ugly kiosk above ground.

- Optional pumped outlet.

- Fully adjustable to suit the number of people using it.

- One piece tank construction - one piece moulded construction ensures no structural weakness.

-

Very small size enables economic installation in tight spaces.

-

The QUANTUM domestic sewage treatment plant recycles its own waste products resulting in less sludge to remove.

- No Primary Settlement Tank - No Primary Tank Odour.

-

Simple and cheap maintenance.

- Cheap and easy installation.

- 20 year tank warranty.

- Can accept raw sewage pumped into it if required.

-

Versatile inlet depths - QUANTUM sewage treatment plants can be supplied for different inlet invert levels.

- Ammonia reduction - incredibly down to 1.8mg/L. Very important for sensitive watercourses.

Accepted by the Environment Agency for discharge to watercourses and ditches, without the need for a permit, if the installation complies with the General and Binding Environment Agency Rules. If you have a ditch locally, Click here to find out if you own the ditch at the other side of your boundary. You may be surprised.

How the QUANTUM Sewage Treatment Plant Works (video below)

Incoming sewage is screened to prevent accidental non-degradable products entering the digestion chamber. The Vibro-Screen™ allows organic sewage solids to enter the tank without problems.

The screened sewage is aerated and a microbial 'soup' develops that digests the pollutants and organic matter in the remaining sewage. These beneficial microbes are constantly topped up with the microbes that settle out at the bottom of the final settlement tank, ensuring a constant supply of bacteria for the digestion process. There is no need to add extra bacteria, as is the case with some other plants.

The treated sewage then enters the final settlement chamber where activated sludge bacteria settle out at the bottom. These beneficial microbes are constantly returned to the aeration chamber, via a Settled Sludge Return (SSR) pipe to the Vibro-Screen, to boost the treatment system performance.

The bacterial scum or crust that forms on the top of the effluent in the clarification chamber is returned to the Vibro-Screen via the Floating Sludge Return (FSR) pipe. This is an innovation originally developed as a feature of our VORTEX sewage treatment plant. Other activated sludge plants need this crust removing, by hand, at regular intervals.

It saves a lot of unpleasant work for both the owner and the service engineer, resulting in lower cost servicing bills.

Most sewage treatment plants struggle to work when they are under-loaded. A good rule of thumb is that if a system is working below 50% of its design capacity, there is not enough 'food' from the toilet solids to either grow, or maintain, a working bacterial population. The QUANTUM sewage treatment plant has solved this problem by having a simple hand-turned valve that can turn the amount of air required either up, or down, depending on the number of people using it. It is a simple solution to a complex problem.

QUANTUM has advanced activated sludge sewage treatment plant features not found in any other sewage treatment plant in the UK.

The only electrical component is a small air blower which operates all the process stages. This is housed in an isolated compartment under the lid. There are no pumps, motors or any moving parts within the working part of the tank.

The QUANTUM Sewage Treatment Plant Process

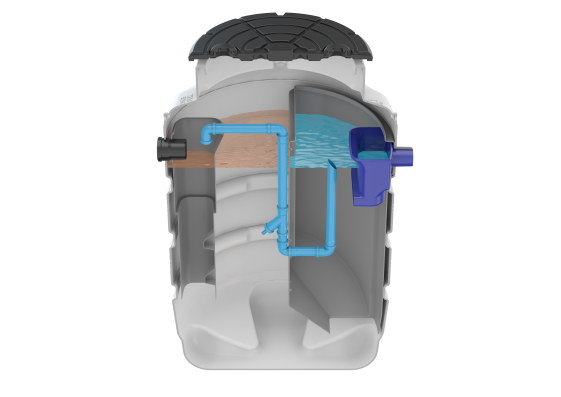

The QUANTUM Sewage Treatment Process (Schematic diagram only - (See Figure 1)

Wastewater from the building enters to Vibro-Screen (1). Here, coarse air bubbles, coming from the yellow pipe, are used to physically break down solid matter and form a mixed liquor with the water.

The mixed liquor flows into the Aeration Chamber (2 ). A bacterial culture is present in the Aeration Chamber which digests the pollutants in the wastewater. The bacterial culture must have a constant oxygen supply and this is provided by a fine bubble diffuser at the base of the tank.

The mixed liquor then flows into the Clarification Chamber (3) where it is able to separate into clear, treated effluent and sludge. The clear effluent is able to flow through the scum baffle and out of the tank.

UNIQUE FEATURE - Simple manual valves allow the air flow to be adjusted. This enables the plan to work at maximum efficiency if it is underloaded. This is a very valuable feature, e.g. for a 5 bedroom house (which needs a minimum 7 person plant) with only 2 people resident. This feature is only available on our QUANTUM and VORTEX sewage treatment plants.

The QUANTUM sewage treatment plant reduced the Phosphorous levels in the raw sewage down to 2.9mg/litre, during its EN12566-3 test.

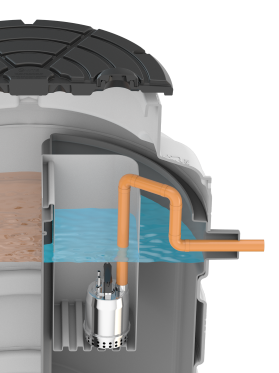

The Sludge Management System (SMS) - (See Figures 2 and 3)

In the Clarification Chamber, sludge accumulates at the bottom (settled sludge) and top (floating sludge) of the tank.

Settled Sludge is 'live' sludge that contains active bacteria that were washed into the clarification chamber with the effluent from the Aeration Chamber.

Floating Sludge is 'dead' sludge that is composed of dead bacteria, which rise to the top, like dead fish do - plus small floating solids and fats.

Air from the blower is distributed by the regulator to two sludge return pipes, Figure 2 shows the Settled Sludge Return Pipe.

This creates a vacuum that sucks the sludge from the bottom of the Clarification Chamber and transfers it back to the Vibro-Screen.

This has several advantages for the treatment system.

It provides additional 'food' for the bacteria in the aeration chamber and allows the plant to re-digest a lot of its waste products, enabling a longer period between emptyings. It 'seeds' the incoming sewage with the correct type of bacteria needed to digest the sewage.

Unique Automatic Floating Sludge Return (FSR) - (See Figure 3)

In all Activated Sludge Process (ASP) sewage treatment plants, dead, floating sludge accumulates at the top of the Clarification Chamber. This sludge must be periodically returned,to the Aeration Chamber, or it will become so deep that it will be be taken into the bottom of the outlet baffle and contaminate the final effluent.

If this happens, it will block the drainage field; which is VERY expensive to replace, or pollute the watercourse that the sewage treatment plant discharges into.

With all other ASP plants, the transfer of this dead floating has to be done, rountinely, by hand, by the owner and it is not a pleasant task.

QUANTUM sewage treatment plants come with the automatic FSR fitted as standard.

The Automatic FSR enables QUANTUM to automatically recycle the floating sludge in the Clarification Chamber back to the Vibro-Screen without the need for the owner to do anything.

Only VORTEX and QUANTUM sewage treatment plants manage their floating sludge this way.

Model (Persons) | Diameter (m) | Height (m)* Standard/Maximum | Inlet Invert (m)* Standard/Maximum | Outlet Invert (m)** Standard/Maximum |

|---|---|---|---|---|

QUANTUM 6 | 1.215 | 2.000/2.450 | 0.550/1.000 | 0.600/1.050 |

QUANTUM 8 | 1.500 | 2.000/2.450 | 0.550/1.000 | 0.600/1.050 |

QUANTUM 10 | 1.500 | 2.000/2.450 | 0.550/1.000 | 0.600/1.050 |

Additional Extras (if required)

*Turret Extensions are available for deeper inlets.

**Internal Pump Stations (IPS) are available if a pumped outlet is required.

QUANTUM sewage treatment plant downloads

Please read Tank Delivery and Off-Loading Information before ordering.