Sewage Treatment Plants - Options for Off-Mains Properties - WTE

QUANTUM Domestic home wastewater treatment plant.

Adjustable, low cost, compact and low energy plant, from £1550 plus VAT delivered.

From 1 to 10 persons.

VORTEX Adjustable sewage treatment plant.

It solves the Low Occupancy problem, faced by other systems.

From 1 up to 30 persons.

CYCLONE Commercial/Domestic home wastewater treatment plant design, that can work down to 20% of its design load.

From 2 up to 5000 persons.

FilterPod Non-Electric sewage treatment plant. It can survive long periods of no use without bacterial death.

From 1 up to 20 persons.

Package sewage treatment plants, septic tanks or cesspits - options for rural properties which conform to the current UK regulations

WTE manufactures several types of sewage treatment plants for rural off-grid wastewater treatment, with prices from £1550 plus VAT.

We make Eco Electric package treatment plants, non-electric sewage treatment plants, domestic and commercial sewage treatment plants. We also manufacture cesspool/cesspit tanks, (where NO biological wastewater treatment takes place).

The usual choice is between a sewage treatment plant and a septic tank. See Which do I need - Septic Tank or Sewage Treatment System? before reading the articles below.

The cost of running the various off-grid residential domestic and commercial systems varies a great deal, so check before you buy.

See our extensive FAQ's page for answers to the most common questions about sewage treatment

Activated Sludge Process (ASP) Sewage Treatment Plants

These types of sewage treatment plants start at £1550 plus VAT and comprise of a single tank, with a smal electric blower inside.

They are suitable for the vast majority of homes.

Our VORTEX and QUANTUM sewage treatment plants recycle their own waste products along with live, settled, beneficial bacteria. They return them back to the digestion chamber to activate and speed up the digestion of the raw sewage.

They don't need any extra bacteria adding during their lifetime as they constantly 'top-up' the digestion chamber with active bacterial sludge from the final settlement chamber.

They are a simple, reliable wastewater treatment solution and tend to be cheaper than 3 stage plants, with a lower electricity cost.

The VORTEX and QUANTUM are adjustable, up or down, for different numbers of people using it. They digest the solids and liquids together in a bacteria rich 'soup'.

They are both activated sludge sewage treatment systems. They have a simple hand-turn air regulator valve to 'turn them down' for low populations and make them into a 'smaller' plant.

The effluent can be discharged into a soakaway drainage field, or a watercourse, subject to the necessary consents

Servicing of most of this type of treatment plant is 6 monthly, but the VORTEX and QUANTUM only require servicing every 12 months. They only need emptying when necessary (depending on how many persons are using them), to remove sludge.

The first extended aeration plants were brought into the UK from America in the mid 1990's. It was said at the time by the original importer, that they did not cope very well with underloading situations. Unfortunately, this information seems to be no longer passed on to the customer by most sewage companies. All, apart from the VORTEX and QUANTUM, work better when reasonably loaded. Our independent testing has shown that VORTEX works at only 10%.

Electrical consumption of most activated sludge plants tends to be higher than that of three stage sewage treatment plants, due to the longer aeration time needed by the process. However, the VORTEX and QUANTUM sewage treatment plants use less than most three stage plants, due to their unique design. A 6 person VORTEX treatment plant only uses 30 watts/hour and can be solar powered to be completely off grid.

Click here for How the VORTEX and QUANTUM are so energy-efficient.

Three Stage SAF & MBBR Sewage Treatment Plants

CYCLONE 3 Stage Domestic and Commercial Sewage Treatment Plants

These type of domestic/commercial sewage treatment systems comprise of a small electrically driven packaged plant, usually all contained in a single tank.

These types of sewage treatment plant are similar but have some key differences.

SAF = Submerged Aerated Filter

MBBR = Moving Bed Biofilm Reactor

The sewage is first settled in a Primary Settlement Tank to remove the solids, which settle to the bottom and form a Sludge. This is removed, usually annually, by tanker.

The liquid part of the sewage passes into the digestion chamber, or 'Biozone', where air is introduced. The organic matter pollutants in this liquid are digested by aerobic (oxygen breathing) bacteria which colonise the media (filter bed).

The cleaned liquid then passes to a final settlement tank stage to remove the fine solids.

The difference between SAF and MBBR is how the media is installed in the tank. In a SAF system the media is static, whereas the media in an MBBR sewage treament plant is mobile. This is a key difference because SAF plants are less able to stop the media blocking becuase "dead zones" always form. More maintenece is required therefore SAF sewage treatment plants have higher running costs due to the requirement to clean and replace the media. MBBR systems constantly circulate the media and "dead zones" cannot form. This reduces the maintenance requirments and improves treatment efficiency.

The treated wastewater effluent can be discharged to a Soakaway Drainage field system, ditch, or watercourse, (subject to Local Authority and Environment Agency Consents, if applicable). Traditional Soakaways are not allowed for sewage systems.

Maintenance, (which can be expensive, particularly for some package sewage treatment systems) and emptying of the plant to remove the settled solids, will be required at regular intervals. This is usually annually for a single dwelling domestic sewage treatment plant and 2 to 6 monthly for a multiple dwelling unit, as the settlement tank is comparatively smaller in larger, multiple house units.

Our CYCLONE three stage wastewater treatment plant is different, as it uses the settled solids in the first Primary Settlement Tank as a source of food for the bacteria in the Biozone. It uses an automatic process to trickle-feed the bacteria, even during holiday periods when no-one is using the sewage system.

Our MBBR & SAF sewage treatment plants cope very well with fluctuating flow rates and underloading, which is a problem with many residential sites, campsites at the beginning and end of the season and pub trade during weekdays.

Most sewage treamnet plants can only work down to 50% of their maximum design loading.

APEX works successfully down to 20% of the design size.

CYCLONE works successfully down to 10% of the design size.

Our FilterPod sewage treatment system uses no electricity for the process and only needs an annual service. They are the most sustainable treatment plants in the UK.

It is our own unique UK design and uses inert RDX media for the filtration. This has the advantage of being non bio-degradable, unlike some of the others of this type.

The liquid is split from the solid waste in the pre-filter tank (or existing traditional septic tank if one is available) and filtered by the media in the second chamber. Bacteria grow in the media and digest the filtered pollutants.

The effluent quality is superb; often better than from most electric treatment plants.

Cesspools and Cesspits - no sewage treatment

Cesspools and Cesspits offer no sewage treatment. NO biological purification occurs and the tank has no outlet. They are simply huge sealed underground tanks where all the wastewater from a property is simply stored until it is emptied by a tanker.

The are always a last resort, when there is no alternative solution.

The MINIMUM size allowed for a one bedroom house is 18,000 litres and for a four bedroomed house, the minimum size is 45,200 litres - massive..

Cesspools need emptying by a licensed waste disposal tanker contractor, and must have adequate capacity to store a minimum of 45 days sewage production. Approval to install a cesspool is required from the Local Authority under the Building Regulations. They will generally only allow one as a temporary measure, i.e. if mains drainage is planned for your village fairly soon. Although they are still allowed in the UK, they are NOT allowed in Scotland or France.

Cesspool systems must be regarded as a last resort as they are VERY expensive to run. The tanker charges for a family of four can be in excess of £9,000/year and it can be very difficult, if not impossible, to sell a house if it has cesspool drainage.

They are useful for Caravan Toilet Waste, but must then have a special coating on the inside, to prevent damage from chemical toilet chemicals.

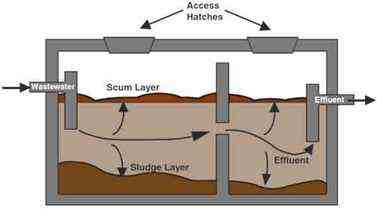

Septic Tanks - limited sewage treatment

Septic Tanks only settle the solids out of the sewage and the septic effluent discharges into a soakaway drainage field. It is illegal for septic wastewater to discharge into a ditch or other watercourse. If you do have access to a ditch then it is much cheaper to instal a sewage treatment plant.

They were the traditional method of residential sewage disposal in rural areas, but they are no longer allowed for over 70% of UK sites. Sewage treatment plants must be used instead.

A septic tank is only allowed for up to a maximum population of 13 people under the Environment Agency General Binding Rules.

Septic tanks are not allowed in Zone 1 of the Environment Agency Groundwater Source Protection Zones at all and even existing ones must be decommissioned. .

Before you choose a septic tank as your method of sewage disposal, there are 3 mandatory tests that must be done to make sure that you are allowed to have one at all.

- You must find out if you are in a Groundwater Source Protection Zone.

- A Trial Site Assessment Hole must be dug to decide the maximum height of the winter water table. Septic tank systems are not allowed if the water table ever gets within 2.1 metres of ground level.

- A Percolation test will be required to determine whether the ground will absorb the liquid efficiently and remove the pollutants. If the ground cannot accept the liquids properly (i.e. CLAY ground is NOT suitable) then it is probable that the soakaway will become blocked very quickly and the system will fail. In any case, septic tank soakaway drainfields do not usually last longer than 10 years as the porous ground becomes blocked with slimy black biomatt and made waterproof by sodium binding. The septic tank should be emptied at least annually.

They operate by settling the solids out of the sewage and then discharging the septic water to a drainage field, to soak away. They offer very limited biological sewage treatment and the effluent from a correctly sized tank still contains about 70% of the original polluting matter. This pollution is partially reduced by the soakaway drainage field system of land drains after the tank. This allows the ground to provide further treatment via soil bacteria before the pollution reaches the groundwater water table. This is vital, as groundwater is used for Public Drinking Water.

The septic wastewater will kill any soil fauna, worms, etc.in the vicinity of the Drainage field though, as.septic tank effluent is extremely polluting and strips the oxygen out of the soil.

Details of how the ground may be used for this partial treatment of sewage are contained in BS 6297:2007.

Reed Bed Wastewater treatment

Vertical and Horizontal Flow Reed Beds

In our experience, you should only consider the Vertical flow reed beds when following a septic tank. We have seen many cases where the effluent coming out of a horizontal flow reed bed, (designed by a firm of ‘expert reed bed designers’) following a septic tank was considerably WORSE than the effluent which went in! As our local Environment Agency officer told me that a reed bed was his first successful pollution prosecution! Click here for more information about reed bed wastewater treatment.

We have stopped our reed bed design work due to the near death of a customer, due to bacteria infecting his hand, whilst doing maintenance to his reed bed.

The vertical flow beds nearly always need electric pumps which are expensive to run, although the system can be operated without power, if an adequate fall is available across the site.

Horizontal flow reeds beds can successfully follow sewage treatment plants as a tertiary treatment but should never be considered as an answer to cleaning septic tank effluent.

Reed Beds are NOT a ‘fit and forget’ item and the wastewater treatment system requires a lot of maintenance, e.g. harvesting and composting the reeds in the Autumn, re-planting, weeding, etc. and annual emptying of the septic tank. They can also smell and act as a breeding ground for flies and mosquitoes, so must not be situated close to dwellings. Children and pets must be kept away from reed beds as they will be paddling in dangerous sewage effluent. All reed bed areas must be fenced.

A Permit to Discharge is required from the Environment Agency.

Contact us for a correct sewage treatment system design for your site.